What is the Bowie-Dick Test Pack?

The Bowie-Dick Test Pack is a critical diagnostic tool used to test the air removal efficiency and steam penetration performance of pre-vacuum pressure steam sterilizers. It is primarily used to check the vacuum systems of sterilizers, such as sterilizers and sterilizing cabinets, for problems such as cold air retention, seal leaks or incompressible gases.

The centerpiece of the bowie dick test pack is a chemical indicator card with a disposable pre-made chemical indicator printed directly on the card.

Bowie Dick Test Pack Details

| Name | Bowie-Dick Test Pack |

| Specification | 115mm*125mm Or Custom made |

| Color change indicator | Yellow to Black |

| Sterilization method | Suitable for Steam sterilization 3.5 min (134°C) |

| Scope of use | Suitable for pre-vacuum pressure steam sterilization |

| Package | 100 PCS/BOX or Custom made |

Description of Bowie-Dick Test Pack

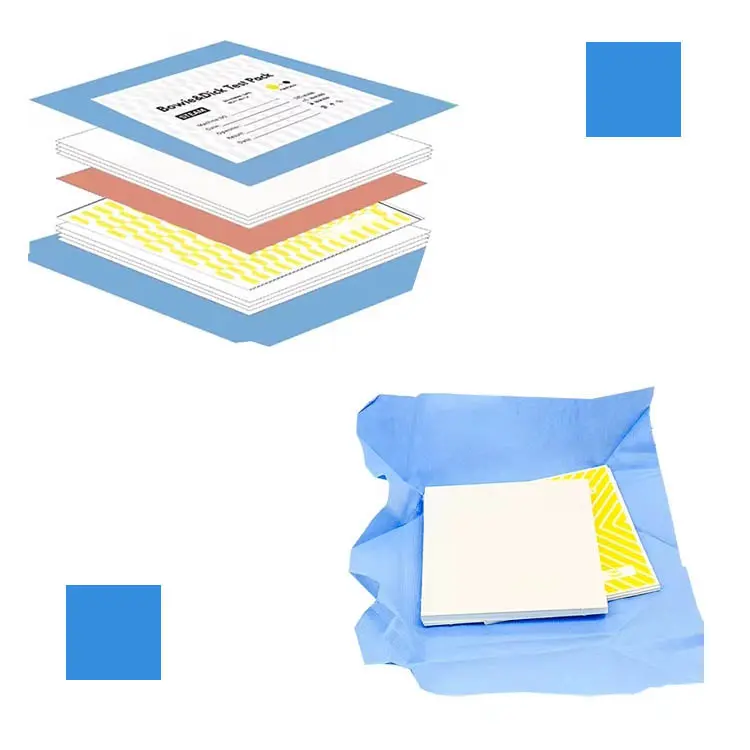

This product consists of a B-D test strip laminating film, laminating laminate, foam board, wrapped in crepe paper and labeled with instructions.The B-D test strip is printed with steam sensitive indicator ink and placed near the center of the laminating material. During the sterilization process, steam can penetrate the breathable laminating film and react with the indicator ink on the B-D paper, making the B-D paper to change from yellow to black.

Why Choose Our Bowie-Dick Test Pack?

- Our test packs are specially designed to provide accurate coloration of indicator cards, clear results, and resistance to high temperatures and pressures to consistently provide accurate test results. It can be kept as a record for archival purposes.

- The indicator card of the test packs is yellow and black. The difference between these two colors is obvious, which can greatly reduce the possibility of misjudgment.

- Our test pack indicator cards are made with non-toxic water-based chemical indicators, free of lead and other heavy metals. They are safe to use.

Application Situations

Our Bowie-Dick Test Packs are in wide usage throughout hospitals, pharma factories, food factories, etc. It is used for:

- Make sure the sterilizing cabinet works fine

- See if steam sterilization machine acts proper

- Follow the rules of sterilization

- Provide a true report for sterilization records

Design Principle of Bowie-Dick Test Pack

The Bowie-Dick test pack is a one-time test pack acting as an air test inside the sterilizer/cabinet. It traps any residual air inside a steam sterilizer cabinet. Because of its big size and permeability to air. The test paper itself is very sensitive to this trapped air so it gives a positive indication if there is no more air trapped within or a negative one otherwise. So it shows if air is all gone or not. This determines whether the sterilization container is sealed properly and can effectively complete the next sterilization task.

Understanding Bowie-Dick Test Paper

Most times:

- If color changes same everywhere in the B-D test paper → Good (air removal and good vapor permeability)

- If see bright spots or color not same → Problem (air still inside, machine needs fixing)

Until the test is passed before normal medical device sterilization can be carried out.

Important for Test Pass

To know test is passed:

✅ B-D test paper turns same black color everywhere = Good

❌ Paper color not same = Failed

Below pictures show different results.

Why B-D Testing?

The moist heat sterilization process consists of a saturated steam process and an air-pressurized process. There are two types of sterilizers that utilize the saturated steam process, gravity displacement steam sterilizers and vacuum type pressure steam sterilizers. Gravity displacement steam sterilizers are not need B-D test.

Vacuum-type pressure steam sterilizers use saturated steam to denature and inactivate microbial proteins. If the sealing performance of the sterilizer is not good, the internal gas residue or the entry of cold air from the outside will make the steam temperature does not meet the sterilization temperature standard. Therefore, before the vacuum-type pressure steam sterilizer sterilization operation, it must be carried out B-D test, to detect the sterilizer cavity air can be completely discharged, whether the sealing is up to standard.

How Often is the B-D Test Appropriate?

How often is it appropriate to perform B-D testing when sterilized containers are in daily use? From the point of view of risk control, it is best to do it every day. But it will also be considered on the basis of the following situations:

Cost:

B-D testing needs to be done empty, which means that an additional sterilization operation is required, which will increase energy consumption, time and the cost of the test kit.

Technology:

B-D testing was invented 60 years ago, and after 60 years of development, today’s sterilization equipment is much more advanced than before. Each steam sterilization cabinet is equipped with a reliable vacuum pump and evacuation program with high precision and reliable sensors. Now, 60 years later, is B-D testing as urgent for risk control as it was 60 years ago?

Therefore, the cycle of B-D testing for evacuation type sterilization cabinets, whether this cycle is half a year, a quarter, a month, a week or a day. It is necessary to make a reasonable choice by combining the process characteristics of your sterilization equipment and local regulatory opinions.

Operation Procedure and Result Interpretation

Test Method: Place the test pack directly above the vapor exhaust port in the empty sterilizer cabinet and run a specific sterilization program (usually 132℃-134℃ for 3.5 minutes).

Result Determination:

- Pass: Uniform color change of the chemical indicator, indicating adequate steam penetration and no air residue.

- Failure: uneven discoloration or light spots in the center area of the test paper (cross part of the most obvious), suggesting that the cold air is not exhausted or seal leakage caused by steam penetration.

Preservation Method

lt is strictly prohibited to expose it to the air for a long time. The storage method shouldbe away from light, room temperature,ventilated, dry and sealed. Prevent moisture, andprohibit contact with acid and alkali substances.